Grimmschirp components are state of the art. With low energy requirements and high capacity, the are very efficient.

Whether they reprocess recycled materials or process virgin fibers, they produce nonwoven grades that meet the increasing demands on the final product in every respect.

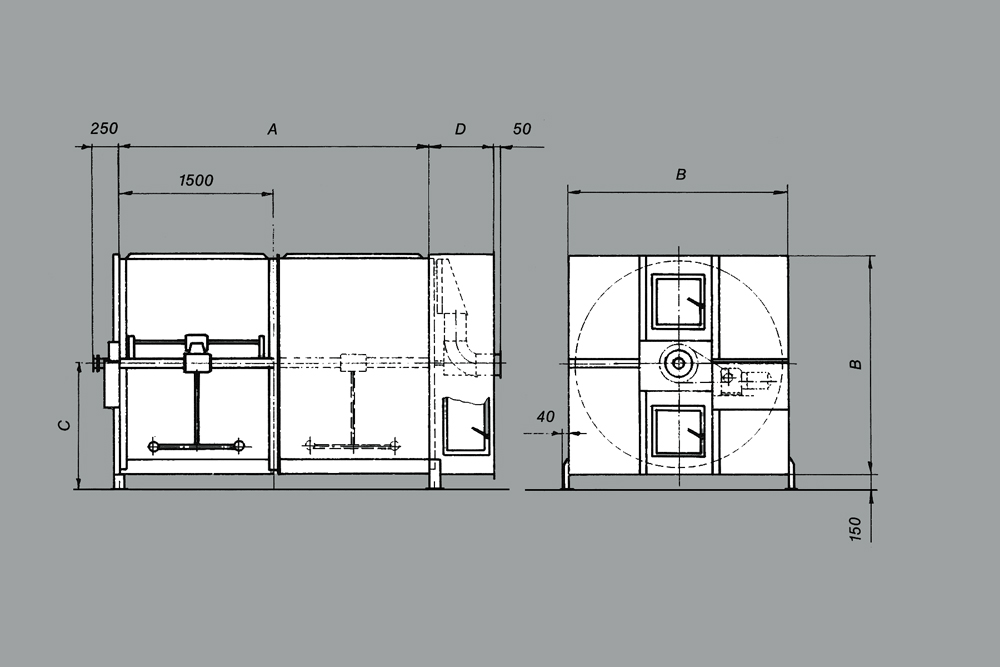

Nonwoven machine, type F04/91

They can process all types of virgin and recycled fibers, such as natural, chemical and synthetic fibers.

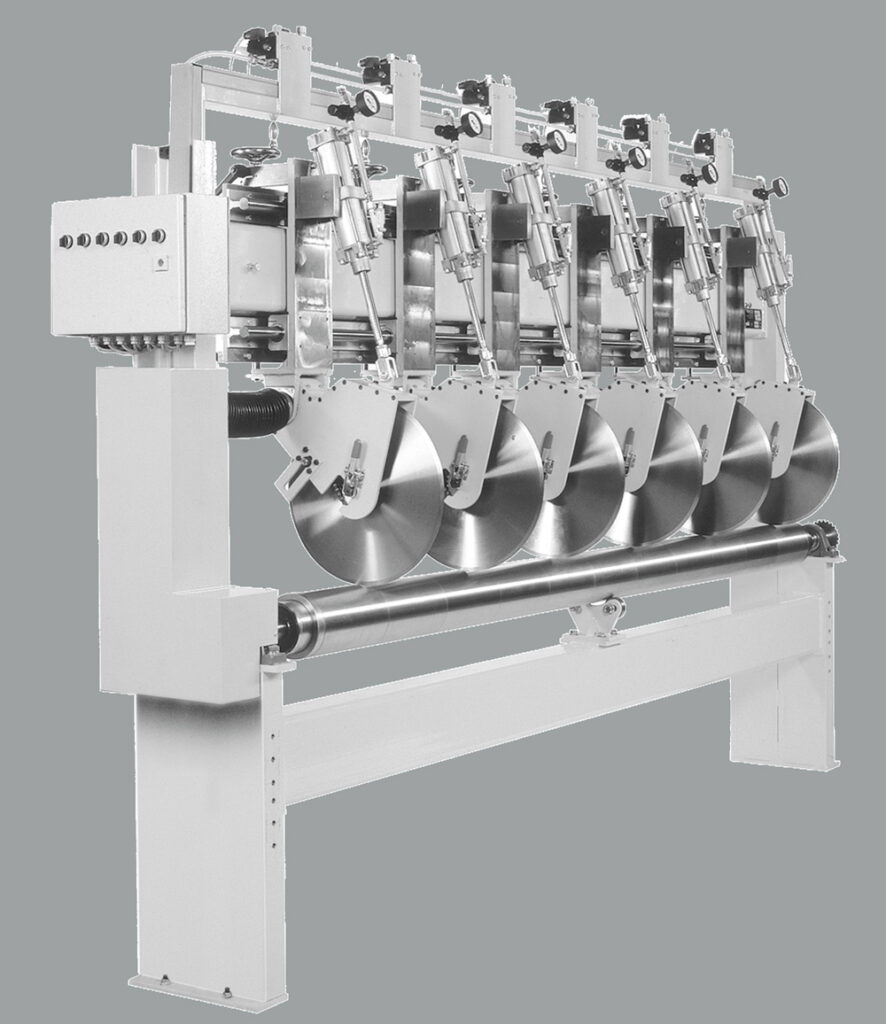

High-performance ripper 38

High-performance ripper for wool, cotton and all types of synthetic fabrics. Top performance, easy handling and maintenance.

Edge opener, type 57

Edge opener with precision adjustable feed speed for needle felt, nonwovens made of natural and man-made fibers, jute and sisal, wool and cotton.

Fine opener, type 65

Machine for opening fiber flocks gently as well as for preparing slightly solid nonwoven waste (edge strips, start-up pieces, etc.).

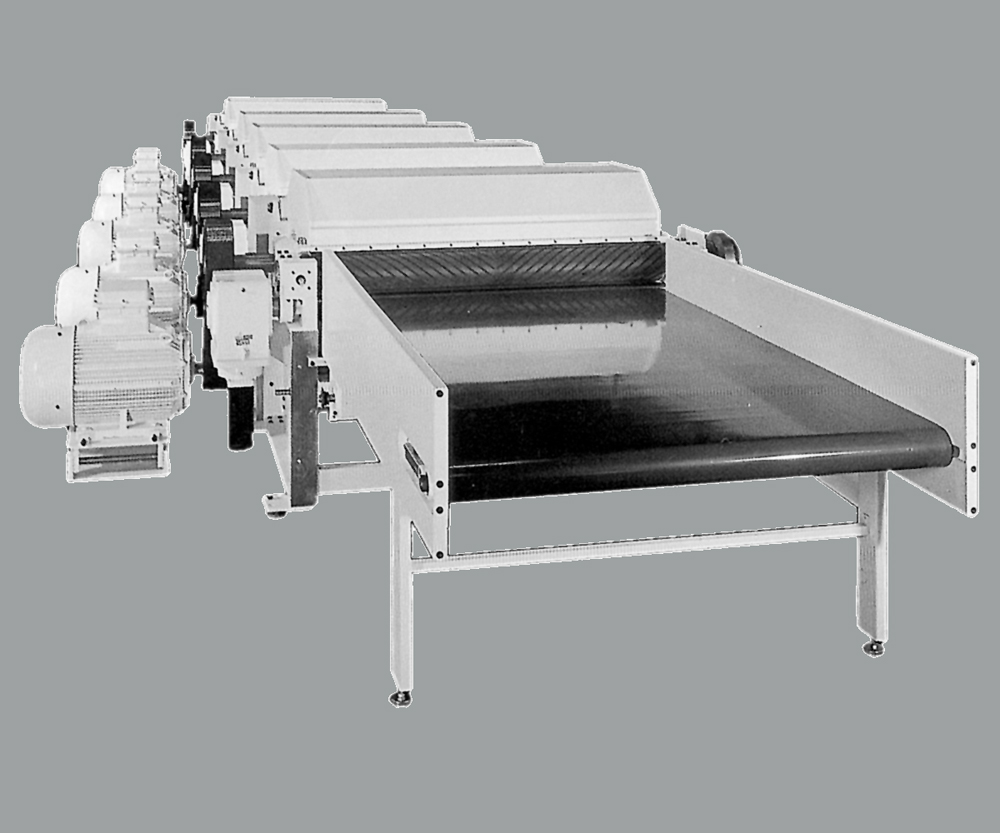

Cutter, type 66

For slitting, cross-cutting and perforating all types of nonwovens; modular system with numerous options.

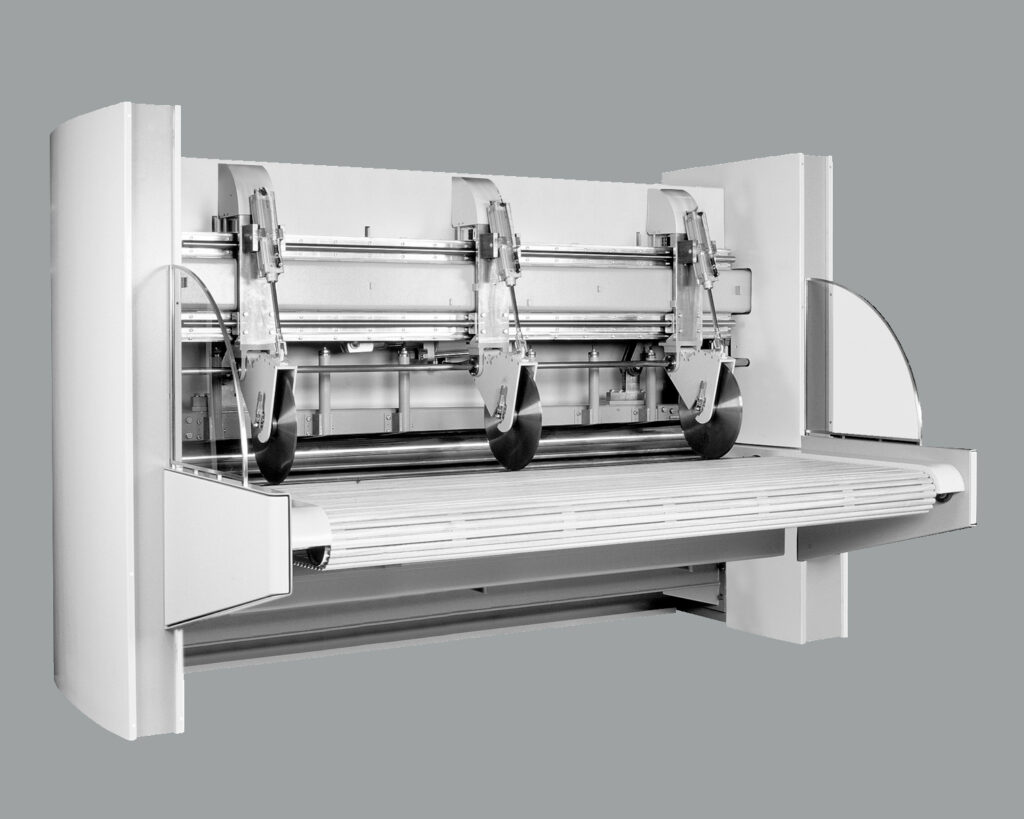

Slitter, type 66 L

A pneumatic system actuates the cutter heads, precision-adjustable pressure, circular blades acting on a 150 mm diameter hardened steel shaft.

Rotary filter, type 71

Fully automatic filter for dedusting large quantities of air. To separate coarse fibers and fiber dust (even when heavily contaminated). Also for paper, plastic, wood, tobacco, leather processing etc).