Machinery from grimmschirp is planned carefully to customers’ specifications and comes as a turnkey solution if you wish. Advanced control technology and components that are perfectly in tune with one another mean that our machinery is highly efficient, reliable and user friendly. You process all types of short- and medium-staple fibers and use mechanical or chemical bonding processes (or a combination of the two). If fibers are prepared properly, web accuracy of less than a 5% CV is achieved.

From planning to creating turnkey machinery and providing production support, we’re at our customers’ side every step of the way to ensure the uncompromising quality and reliability they expect.

Grimmschirp’s technology can process almost any type of fiber. Traditional textiles as well as filaments, coconut, jute and sisal products, needle felts, carpeting and much more. Even ceramic, carbon and Teflon fibers, which are considered problematic, can be recycled.

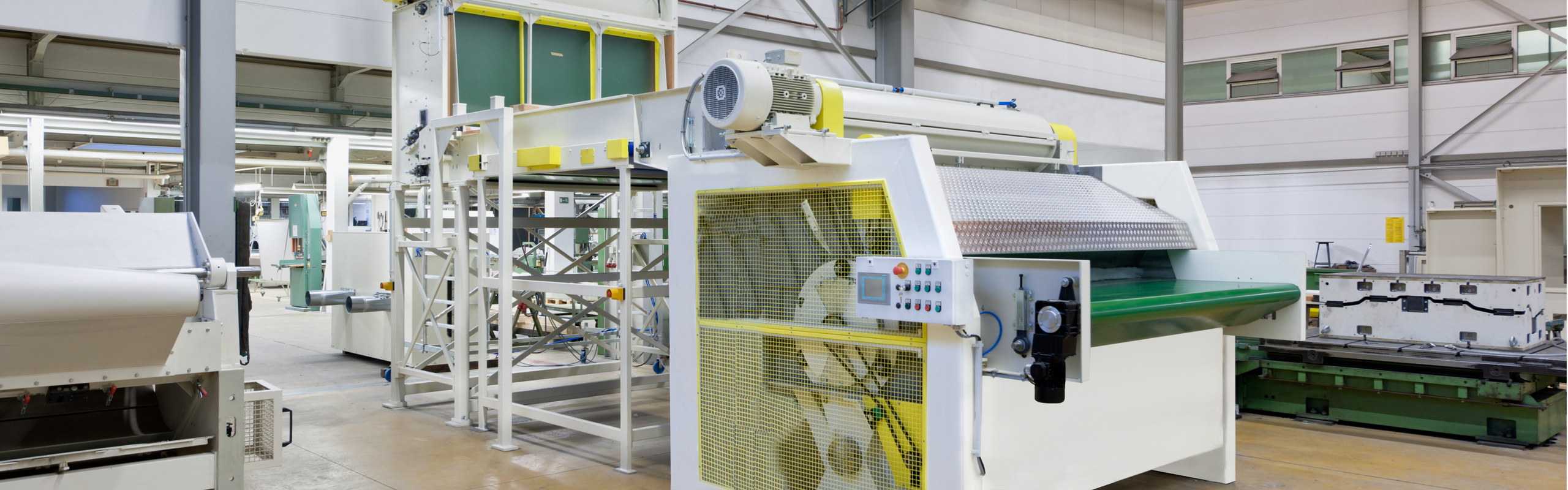

Natural fiber nonwoven machine

Natural fiber nonwoven machine with air-carding technology and bonding with needling machines in two stages. This machine stands apart because it can produce thin nonwovens (from 150 g/m²) at high velocities.

Heavy-nonwoven machine

Heavy-nonwoven machine with Airlay technology with thermoplastic or thermoset nonwoven bonding. The machine excels at making very uniform area densities.

Blow molders for fibers

A blow molder for fibers with thermoplastic nonwoven bonding. This machine stands out because it makes complex molded parts with virtually no waste.