Models, molds and tools play a key role in guaranteeing the quality of the parts produced and ensuring that production is efficient and stable.

Grimmschirp has all the resources required at several well-connected sites to carry out sophisticated projects at a high level of precision.

Project management

A designated contact looks after customers throughout all project phases. This person is the expert in terms of concept development, engineering and production. They are there from the outset to ensure the right course is adopted.

CAD/CAM

The team in our CAD/CAM department uses CATIA V5, Tebis and Work NC and knows everything there is to know about making models and tools. Therefore, smart tooling concepts, efficient manufacturing and molds for minimum material consumption during production are guaranteed.

Mechanical and manual production

We consistently invest to ensure our machines can handle the ever-increasing challenges technology presents. Which is why grimmschirp has state-of-the-art, multi-axis CNC machines in various types and sizes.

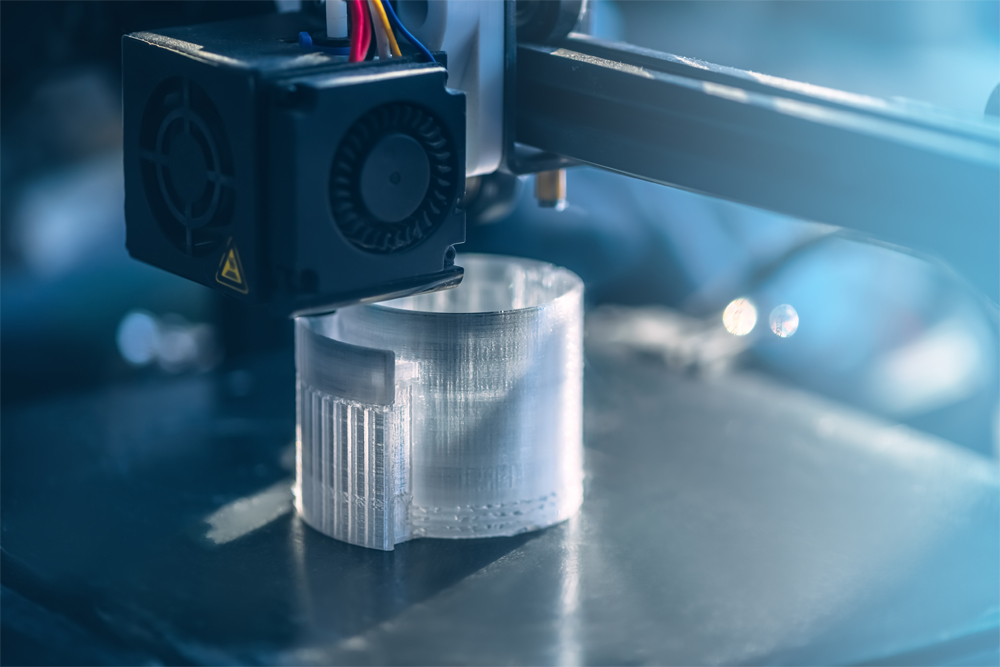

Additive manufacturing

Over the last few years, we’ve seamlessly incorporated pioneering technologies like 3D printing into our concepts and manufacturing processes. Multiple 3D printer sizes can process PLA, ABS, FDM, TPU, ULTEM and nylon LF for instance.

Quality management

Achieving quality is a process that needs to be planned. We provide in-depth support and the right concept at the beginning and inspect everything thoroughly at the end. A high level of vertical integration, a robust quality management system and, above all, a workforce that takes quality seriously, guarantee superior precision. State-of-the-art 3D measurement equipment (measuring arms and software from various manufacturers) help us to do our job. The team in our own technical center can inspect and try out tools and their peripheral devices to ensure they work. All sites have ISO 9001:2015 certification.